Pioneers in vehicle comfort

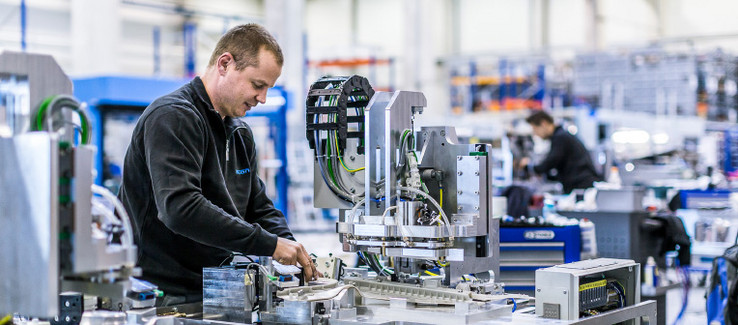

Vehicle manufacturers and their suppliers worldwide are able to employ a high degree of automation in the production of comfortable interior fittings for automobiles by using 3CON’s customised tools and production systems.

Vehicle manufacturers and their suppliers worldwide are able to employ a high degree of automation in the production of comfortable interior fittings for automobiles by using 3CON’s customised tools and production systems. Since 2015, 3CON have been developing and designing electrical and pneumatic components and control cabinets using EPLAN’s fully integrated software products which function according to standardised data. The upgrade has not only helped 3CON to improve the quality of its documentation but has also cut processing times in half. Drivers and passengers of premium range cars expect flawless workmanship in a vehicle's interior fittings. No exposed metal due to gaps; seams between two pieces of leather follow the contour of the armrest precisely; no creaks from the bodywork, even under heavy acceleration or cornering at speed: in short, the interior gives a sense of superior quality as well as of comfort and security.

Production systems for vehicle interiors

Such a level of quality can now also be enjoyed in mid-range vehicles and not just those from the premium range. This has been made possible through automation which has now also reached high levels in this specific area of automobile manufacture. Parts and modules such as door and side panels, internal mirrors, roof linings, mats, fans, trays and coverings for car interiors are not generally produced by the automobile brands themselves but by suppliers using automated production systems developed and designed to their specific requirements. One of the world leaders in the production of such systems is 3CON Anlagenbau GmbH. Founded in 1998 in Oberaudorf in Bavaria, Germany, the company headquarters are in Ebbs in the Austrian state of Tirol. Here, the firm develops and produces innovative tools and equipment for hot air-cutting, press laminating, vacuum laminating, edge folding, and joining technology as well as complete assembly lines for the production of interior fittings for vehicles. “Up to 2011, only tools were being designed and produced,” says Thomas Neuschwendter, who joined the company then as an electrical designer. “The development of production systems was introduced only four years ago as a logical next step in enabling customers to benefit from our extensive experience in toolmaking.”

Economising in the wrong place

3CON’s operations cover support for component development, research into materials and processes, process optimisation including simulation and prototypes, conception and design, as well as the development, installation, and on-going maintenance of production systems. Since the very beginning, 3CON technicians have been using one of the market-leading software packages for 3D CAD used widely across the automobile industry. In contrast, for electrical design – which had a much narrower scope then than it has today –a product from a less well-recognised firm was chosen on grounds of cost. “Since some clients want the design documents for re-use in the EPLAN format, I had become familiar – both at 3CON and at previous employers – with the extensive and easy to use options offered by this software,” says Thomas Neuschwendter. “The package we had been using was increasingly coming up against its limitations so at the end of 2014 I decided to upgrade to a tool that would better support the broader range of tasks in production systems engineering.”

Instantly fully equipped

3CON production systems require expertise in a range of areas covering electrical and pneumatic drive engineering and positioning technology – including robotics – and the construction and control of heating elements to activate the adhesive used in joining and lamination processes. Thomas Neuschwendter describes the complexity of the systems: “Some systems, with up to 20 axels, are highly drive-train dependent; others have in excess of 500 inputs and outputs. The electrical designs for a typical system can fill three folders. That means about 1,500 pages which, using the previous software, was extremely time-consuming to work through and maintain because the old system lacked much of the automation that is a matter of course in EPLAN.” For 3CON, partial solutions were out of the question when upgrading the electrical design. To avoid system breaks between the individual functions within the system, the company opted for EPLAN Electric P8 for electrical design, EPLAN Fluid for the configuration of the pneumatic and/or hydraulic components, and EPLAN Pro Panel for the 3D design of control cabinets.

Investment in a configurable project

During the upgrade to the new software, 3CON did not transfer data from the previous system. EPLAN is used whenever new system parts are needed so that old stock is undergoing gradually replacement and time spent in conversion is being avoided. However, time was invested in enabling 3CON’s three-person electrical design team to then save a great deal of work later. “The first system we designed with EPLAN was planned with every possible option even though the project did not require it,” Thomas Neuschwendter explains. “This is how a virtual 150% system came about. It can be configured with minimal effort by deselecting any components not required.”

Up to 60% faster

All EPLAN products are systematically constructed using a common database which therefore ensures data compatibility between all components in the overall system. The system can therefore accommodate all dependencies. The addition or deletion of an option in one aspect of the design – for example in the schematic– is automatically effected in all other sub-plans such as for terminal diagrams or switch cabinet engineering. Electrical designers can thus fully rely on the software and are no longer required to monitor and reproduce each change in each component design as was previously necessary. This has been partly responsible for speeding up the subsequent evaluations, which significantly reduces work. “A project that we would have spent a week working on with the previous software can now be done in two or three days,” confirms the electrical designer. “This makes a valuable contribution to our competitiveness because it significantly affects how 3CON can react extremely quickly to individual client requests.” Author: Peter Kemptner / X-Technik